ECoCr-A Hard Facing Electrode Stellite 6 Welding Electrode Engine Valve Turbine Blade

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Shape | Electrode | Hardness (HRC) | 36-45 |

|---|---|---|---|

| Density | 8.44 G/cm3 | Melting Range | 1285-1410 ºC |

| Product Name | Cobalt Base Electrode | AWS / ASME | A5.13 / SFA5.13 ECoCr-A |

| Material | Co Cr W C Ni Mo Fe Si Mn | Dimensions | 3.2-6.0mm |

| Equivalent | Stellite 6, BISHILITE (MHA) No.6, Weartech WT-6, Stoodite 6 | Application | Engine Valve, High Temperature Valve, Turbine Blade |

| Certificate | ISO 9001 | Test Report | Mill-certificate |

| High Light | ECoCr-A Hard Facing Electrode,Hard Facing Electrode Stellite 6,stellite 6 welding electrode |

||

Stellite 6 Welding Electrode ECoCr-A Electrode Hard Facing Electrode Engine Valve Turbine Blade

WLCo6 cobalt-chromium-tungsten alloy cobalt base surfacing welding electrode, Dc reverse connection, with good comprehensive performance. It is considered the industry standard for general wear applications and has excellent resistance to many forms of mechanical and chemical degradation over a wide temperature range, while maintaining reasonable hardness levels up to 500°C(930°F). At the same time, it has good impact resistance and cavitation resistance. WD-Co6 is ideal for a variety of surfacing processes and can be machined with carbide cutting tools. Examples include seats and gates, pump shafts and bearings, corrosion protection devices and rolling couples. It's usually self-mated.

Common Names: Stellite 6, Polystel 6, Hoganas 2537

Standard:AWS / ASME: A5.13 / SFA5.13 ECoCr-A

Chemical Composition(%)

|

Co

|

Cr

|

W

|

C

|

Ni

|

Mo

|

Others

|

|

Bal.

|

27-32

|

4-6

|

0.9-1.4

|

<3.0

|

<1.0

|

Fe, Si, Mn

|

|

Hardness |

Density |

Melting Range |

|

36-45 HRC |

8.44 g/cm3 |

1285-1410 ºC |

Specification

|

AWS / ASME: A5.13 / SFA5.13 ECoCr-A |

|

|

Metal to metal Wear |

Excellent |

|

Cold / Hot Abrasion |

Good / Good |

|

Erosion / Corrosion |

Excellent / Excellent |

|

Impact |

Excellent |

|

Magnetic |

No |

|

Deposit Layers |

2 Max |

|

Thermal Conductivity |

14.82 W/m.K, 102.7 Btu-in/hr/ft2/°F |

|

Electrical Resistivity |

106 μ-ohm.cm, 41.7 μ-ohm.inch |

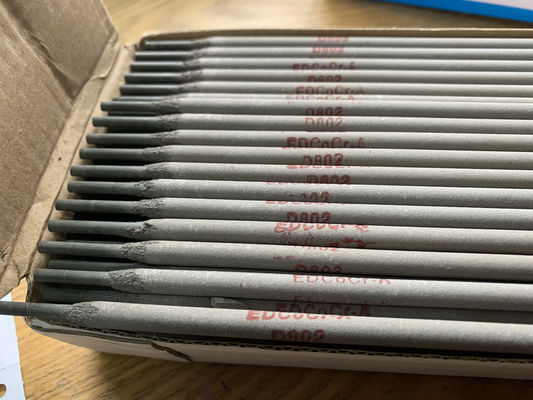

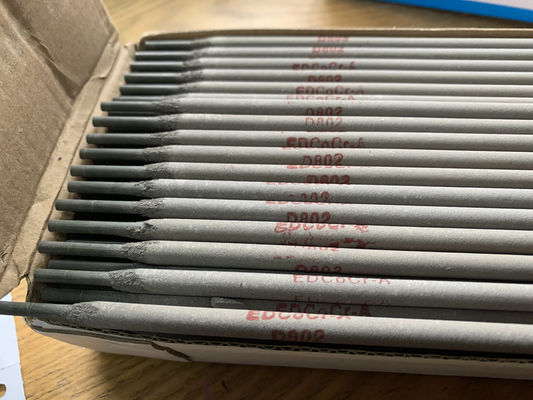

Packing Details

For length 350mm 5kg per Vacuum Pack, 1 Vacpak inside a Carton

a carton 4 packs a total of 20kg, then put them in wooden boxes or trays.

Packaging details can also be customized according to customer requirements.

![]()

Applications

Used to Engine valve, high temperature valve, turbine blade

Type We Could Offer

|

Trademark |

Nominal Chemical Composition |

HRC |

Application |

Reference Standard |

|||||||||

| C | Cr | Si | W | Ni | Fe | Mn | Mo | Co | others | ||||

| WL Co1 | 2.1 | 30.0 | 1.0 | 14.0 | ≤3.0 | ≤5.0 | ≤2.0 | ≤1.0 | Bal. | <1.0 | 48-54 | Valve seat insets, bearing, sawteeth, rotary ring, Pump Sleeves | Stellite 1, ECoCr-C |

| WL Co6 | 1.0 | 29.0 | 1.0 | 4.5 | ≤3.0 | ≤5.0 | ≤2.0 | ≤1.0 | Bal. | <1.0 | 38-44 | Engine valve, high temperature valve, turbine blade | Stellite 6, ECoCr-A |

| WL Co12 | 1.4 | 30.0 | 1.4 | 8.5 | ≤3.0 | ≤5.0 | ≤2.0 | ≤1.0 | Bal. | <1.0 | 44-50 | Pressure valves, sawteeth screw fights | Stellite 12, ECoCr-B |

| WL Co21 | 0.2 | 28.0 | 1.0 | ≤3.0 | ≤5.0 | ≤2.0 | 5.5 | Bal. | <1.0 | 20-40 | Fluid valve seat, turbine blades, hot forging die | Stellite 21, ECoCr-E | |

| WL Co25 | 0.15 | 20.0 | 1.0 | 14.0 | 10.0 | ≤5.0 | ≤2.0 | ≤1.0 | Bal. | <1.0 | 22-40 | High temperature and corrosion-resistant valve sealing surface, pressure casting dies, etc. | Stellite 25 |